New type of double spiral hole pipe

Release time:

2022-07-28 11:14

Source:

Source

Technical prospects:

In recent years, the double spiral inner cold hole drill is more and more widely used, spiral cooling makes the tool in the processing of cooling lubrication effect is better, the drill chip breaking is better, will not occur iron winding phenomenon, the tool is more wear-resistant, has been widely used in engine, mold, wind power and other industries. Cemented carbide double spiral internal cold hole pipe with the domestic drill is widely used, the demand for such pipes also continues to increase, for this reason, our special organization of technical personnel on the new double spiral hole pipe research and large-scale production.

Technical key:

The high-precision extrusion die is manufactured, and its hole control core rod adopts memory titanium metal (that is, it has ultra-high strength and can restore the prototype after deformation), fine raw material control, unique molding agent and its mixing process, and digital extrusion molding.

Technical route:

This project is based on several stages of cemented carbide production: ingredients-oxygen control-carbon content control-mixing of molding agents-extrusion molding-sintering-inspection-finished products.

Technical indicators:

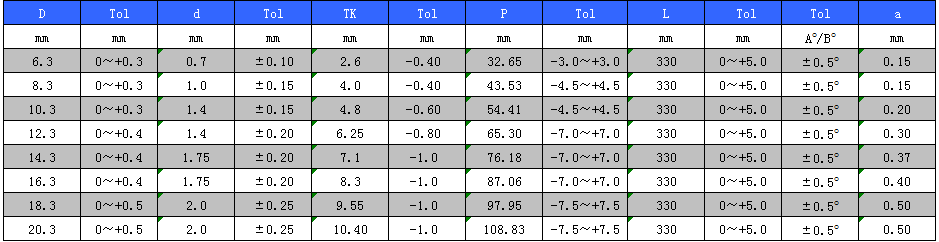

1. The minimum inner hole accuracy of the product is controlled at plus or minus 0.1mm.

2. The minimum hole deviation is controlled at plus or minus 0.15mm.

3. The helix angle of the inner hole is controlled at plus or minus 1 degree.

Product specifications:

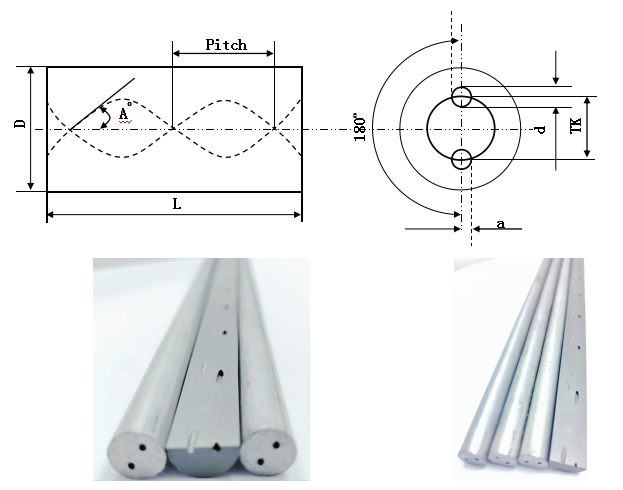

Model representation: D× 2d × TK× L× Bo(L represents length, Ao and Bo represent helix angles 30o and 40o respectively)

Can be customized according to customer requirements of other specifications of the blank.

Rods with two coolant ducts,30o&40o helix

Type specifications:D×2d×TK×L×Bo(L indicates the length, A&B indicates helical angle of 30o&40o respectively)

It can be supplied at customers'requests.

scientific research strength

Zhuzhou Lianxin Metal Co., Ltd. has its own ultra-fine tungsten carbide production line to fully guarantee the extreme uniformity and quality consistency of raw materials, and has international advanced production equipment, testing instruments and process technology. The company takes stirring ball mill (UP company in the United States), extruder (Dorst company in Germany), sintering furnace (ALD company in Germany), numerical control processing and other dozens of domestic and foreign production equipment as the main body, and is equipped with complete testing equipment to form a flexible production line for hard alloy bars, pipes, profiles and other products. High cleanliness of the plant, scientific management system and strict operating standards, to ensure that the standard operating environment to manufacture the most high quality products.

Set product testing, quality analysis, precision measurement, physical and chemical tests in a research and development department, can carry out hard alloy bars, pipes, profiles and other products of the test and quality analysis. At present, the research and development capabilities of Lianxin Metals have been continuously strengthened. In terms of product and technology research and development, quality analysis, and quality control, Lianxin Metals has reached a high level.